Ceremony marking the opening of Thai Yazaki Electric Wire (1962)

Episodes in Yazaki’s global expansion

In this section, see various episodes in Yazaki’s

global expansion at a time when few Japanese companies did business overseas.

HOME Episodes in Yazaki’s global expansion A spinning and weaving business established with prudence and forethought at all levels, including cotton cultivation

1964 THAILAND

A spinning and weaving business established with prudence and forethought at all levels, including cotton cultivation

Saving a partner from woeful circumstances

One day in August of 1964, just two months before the Tokyo Olympic Games began, a send-off party for employees being sent to Thailand was held in the courtyard of Yazaki’s headquarters in Tamura-cho, Tokyo (now Nishi-Shimbashi, Minato Ward). The employees’ destination in Thailand was Taisei Textile, a spinning company operated by Thai Chinese. Yazaki had just officially opened Thai Yazaki Electric Wire the previous year, thus taking its first step into an overseas market. Including the trial operation period, the new company’s factory had been operating smoothly for about two years. Yazaki’s entry into Thailand came from a cherished wish of its founding president, Sadami Yazaki. Made prudently and with forethought, it was designed to realize Sadami’s desire to build a strong business connection with the Thai Chinese who played a prominent role in the Thai economy in order to someday develop business in China. Indeed, Zhang was a prominent figure in Thailand’s economy and one of Thai Yazaki’s Electric Wire’s investing partners.

However, Taisei Textile, which was managed by Zhang, suffered from aging facilities and was struggling. In response to an order from Sadami to “save our partner’s business,” Yazaki quickly organized a team made up of experts in the spinning business to study ways it could provide support. At the same time, Sadami selected members for a second team that would support the first team. Five young employees were sent to train at a weaving machinery manufacturer in Japan. They completed a tough training schedule and were dispatched to Thailand.

Based on its members’ experience rebuilding unprofitable organizations, the study team informed President Zhang that his company would likely fail if it retained its old facilities. The decision was therefore made to build a textile factory possessing the latest facilities on the grounds of Thai Yazaki Electric Wire (Papa-den) with financing from the Export-Import Bank of Japan. Thus, Thai Yazaki Mahaguna Textile Company was born. It is said that one study team member exclaimed, “Now I see why those young guys were training so hard. It was all for today!” when he first realized the accuracy of Sadami’s foresight.

Integrated production, from cotton cultivation to cloth

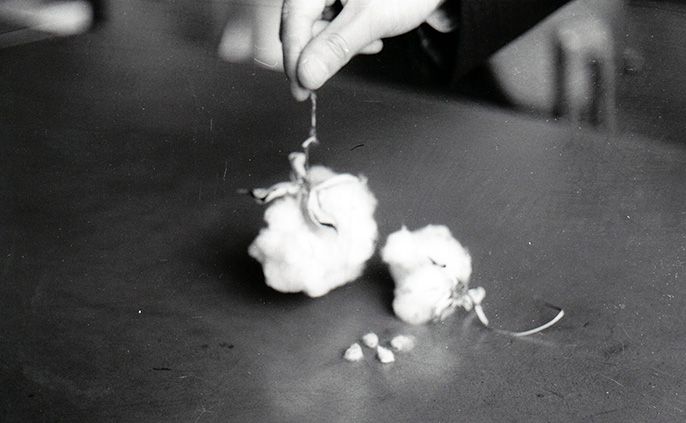

But this was not the end, as Sadami had an even bigger dream. Around that time, one after another, Japan’s traditional textile companies started launching operations in Thailand. Thus, some powerful new rivals were suddenly on the scene. Against them, a small and weak company like Thai Yazaki Mahaguna Textile, which had been hastily put together and used foreign cotton raw materials purchased through trading houses, stood little chance of success. Knowing this, Sadami put forth the idea of procuring raw cotton locally through independent cultivation. He was certain that if Thai farmers were given instruction on cotton farming, such procurement could simultaneously contribute to regional development. Yazaki immediately sent three new agricultural university graduates who had studied cotton production to Thailand. The three began trial cultivation at Khon Kaen and Kanchanaburi. In 1967, the company built a factory and warehouse for the processing of raw cotton purchased from contracted farmers. These facilities were later moved to Chiang Khan in Loei Province, near the border with Laos. The raw cotton was sent to a spinning factory in Bangkok, and the cottonseeds, from which high-quality cooking oil was obtainable, were exported to Japan. In this way, an integrated domestic production system that covered everything from raw materials to cotton cloth had been established in Thailand.

Thai Yazaki Mahaguna Textile Company’s success here was highly commended by Thailand’s Ministry of Agriculture and Cooperatives, the Export-Import Bank of Japan, and others, and attracted observers to the Khon Kaen Factory day after day.

Thus, the company’s spinning and weaving business had become an astounding triumph. However, its success did not last long, as the increasing popularity of synthetic fiber products began casting a shadow on demand for cotton products. At the same time, Japanese car manufacturers began streaming into Thailand, leading to a flood of wire harness orders for Thai Yazaki Electric Wire. As a result, the spinning and weaving business and its employees were sold to a Thai Chinese interest. Operating under a new name, Thai Arrow Products, the company moved on to launch a new automotive parts business. And with that, the story of Thai Yazaki Mahaguna Textile Company came to an end.

EPISODE SELECTION

EPISODE 01 Yazaki takes its first step overseas to Thailand before the Tokyo Olympics.

EPISODE 03 American Yazaki steps forward at a time when “Made in Japan” had a poor reputation.

EPISODE 04 Yazaki is the first to enter the European market! Offense is the best defense.

EPISODE 06 Yazaki’s arrow mark makes its appearance in Gaia, Portugal.

EPISODE 07 Demonstrate and then let others take over: The Yazaki Way takes root in Vietnam.

EPISODE SELECTION