R&D

Research areas

We provide fundamental technologies that serve as the core of our products and support monozukuri.

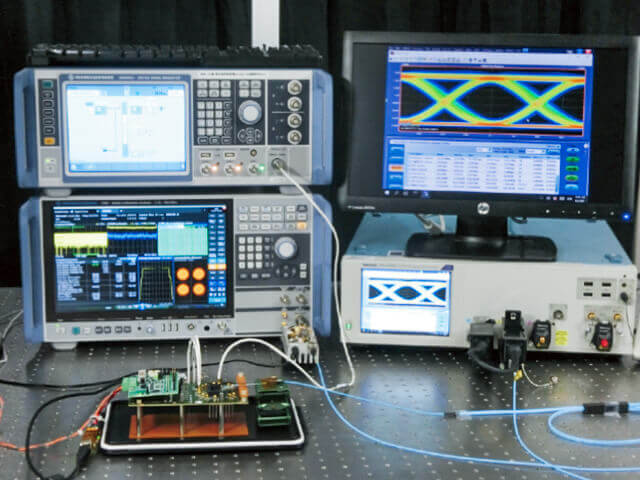

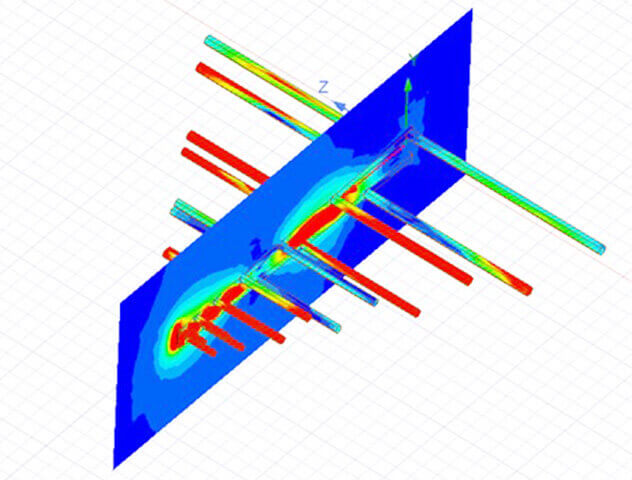

Transmission technology to enhance the functionality of next-generation in-vehicle communications

We conduct research and development on elemental technologies for higher speed and higher reliability of in-vehicle communications and higher frequency of out-of-vehicle communications, which are expected to be necessary for future mobility.

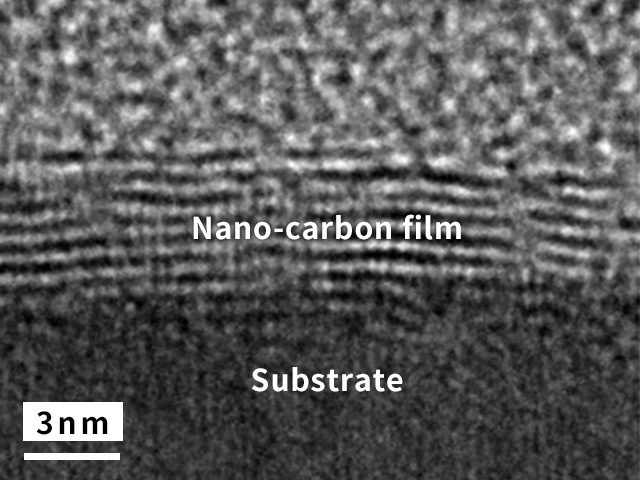

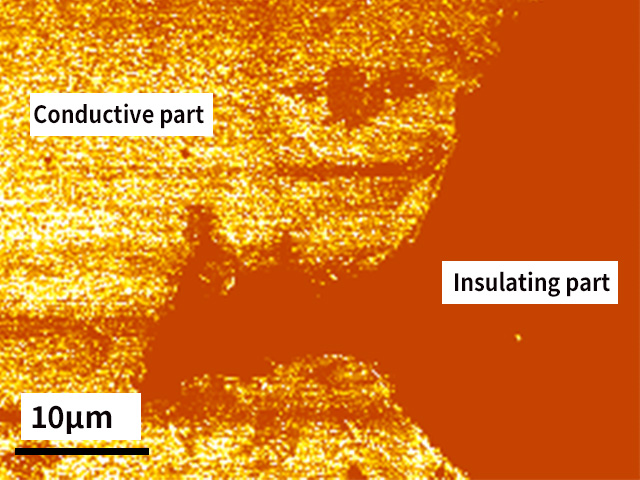

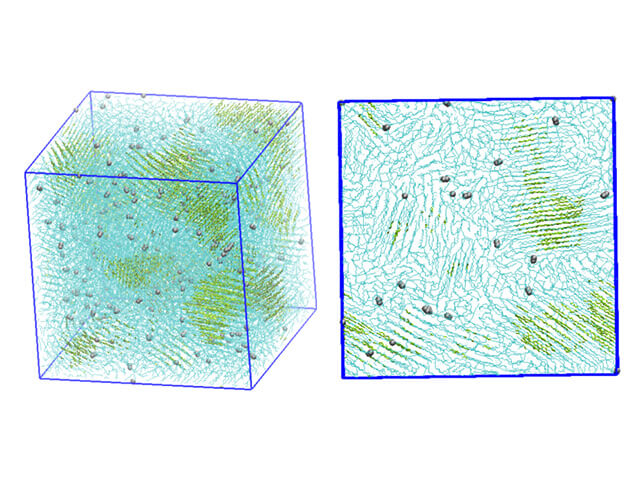

Nano-technology and fundamental material technology for next-generation automotive, environmental, and energy technologies

We conduct research and development to build elemental technologies for conductive, insulating, and various functional materials necessary for creating added value and effectively utilizing energy in next-generation wire harnesses.

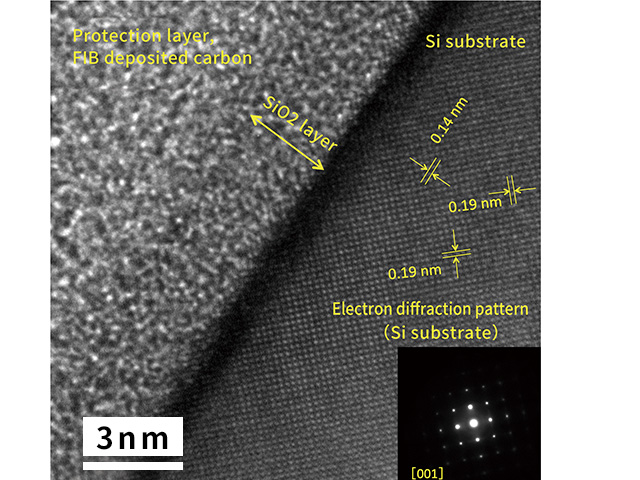

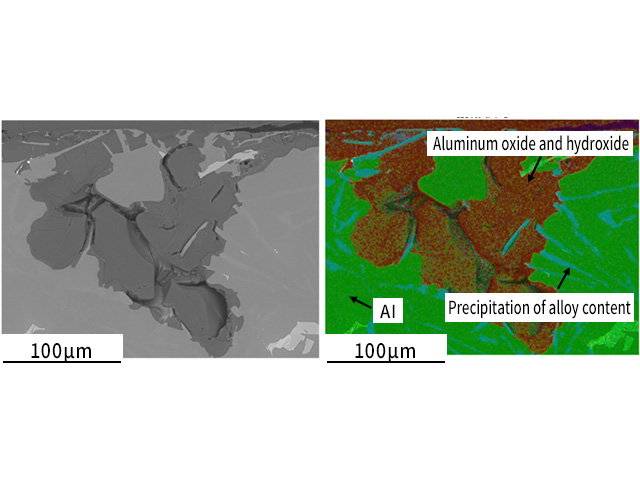

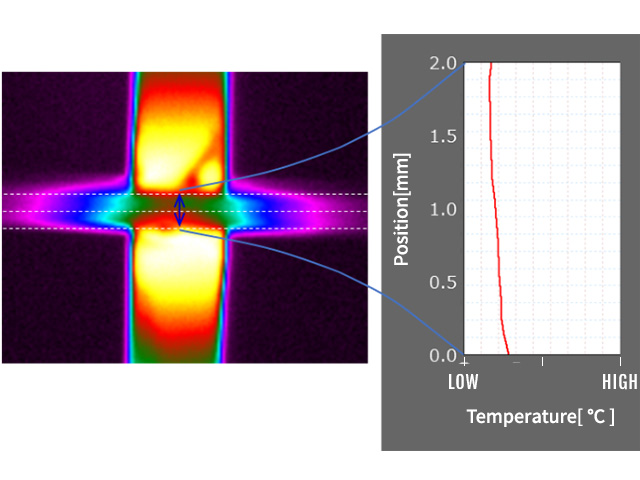

Material evaluation and analytical technology for material reliability that support the preservation of functional properties

We are building advanced analysis technologies for the future while strengthening the basic technologies for evaluation and analysis of materials necessary for the Yazaki Group's existing business. We use a variety of analytical instruments and evaluation facilities to add a measurement informatics perspective to meet the growing needs.

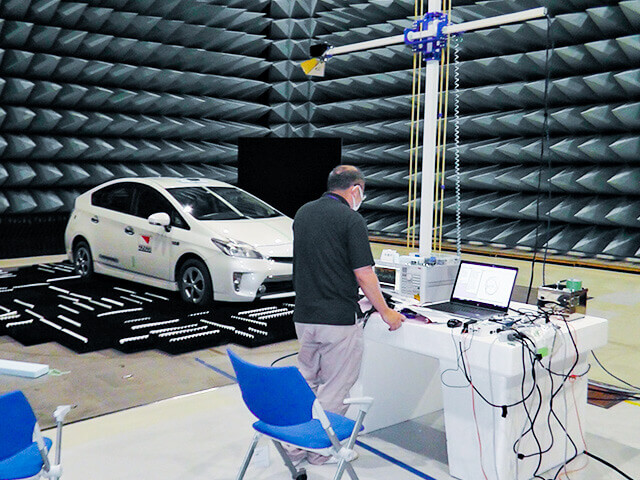

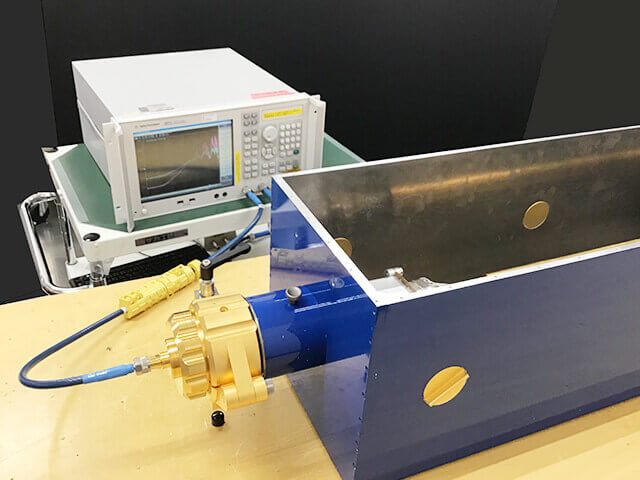

EMC & related systems evaluation technology for transmission system reliability to avoid loss of function

We will establish the EMC & related system evaluation/analysis technology that responds to the increasingly severe electromagnetic wave environment, such as the diversification of radio wave usage environments and the increase in high voltage and current due to the evolution of xEV.

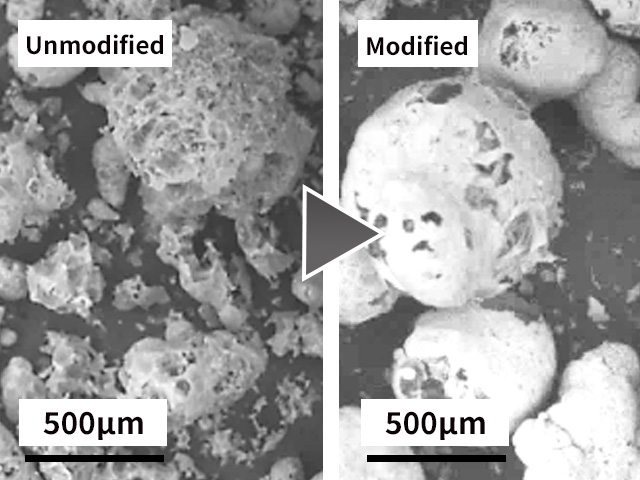

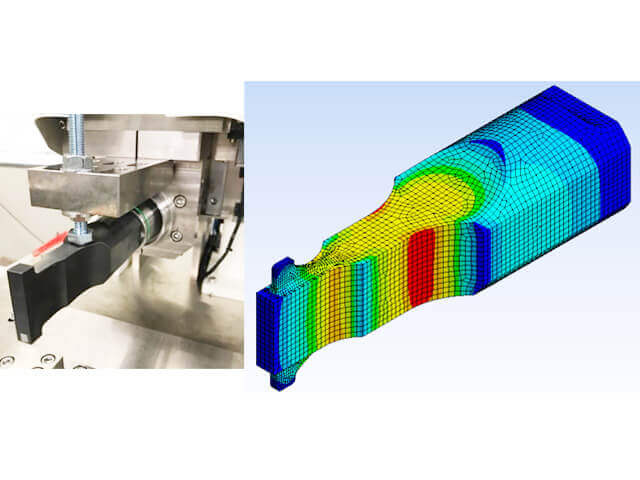

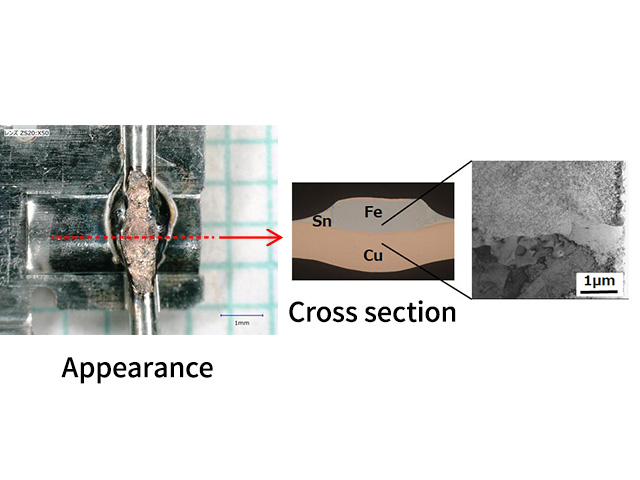

Welding technology for reliability of welded connections that creates continuity of functional properties

With the evolution of xEVs, the demand for materials has changed to high voltage and high current. We support the evolution of the product group by investigating the joining technology from the process analysis.

Advanced technology to explore new areas

In view of the changes in the social environment facing the Yazaki Group, we accelerate the acquisition of advanced technologies through cooperation with universities and research institutions and diversification of cooperation with other companies, and promote research and development that will lead to the development of future technology and business areas.