Main equipment and facilities

Details

The Research and Technology Center applies state-of-the-art equipment and our accumulated know-how to advance R&D. Our fundamental technologies provide technical support for the Yazaki Group’s monozukuri manufacturing systems.

Material evaluation and analysis equipment

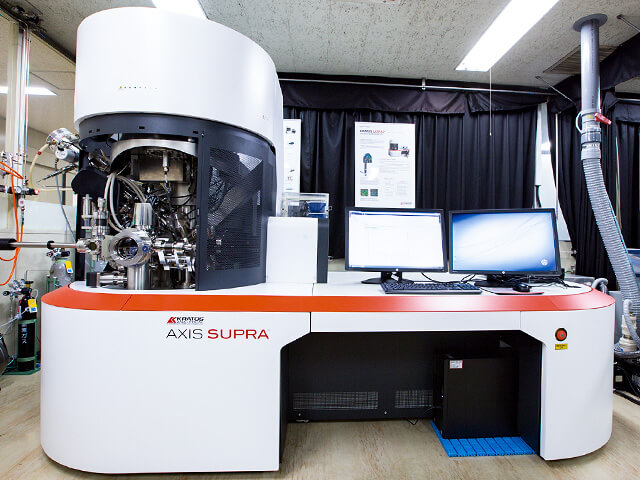

X-ray photoelectron spectroscopy (XPS)

Analysis of composition and chemical bonding states at several nanometers on the surface of a material

Example:

Analysis of functional groups on modified surfaces of fillers used in electrical wire insulation.

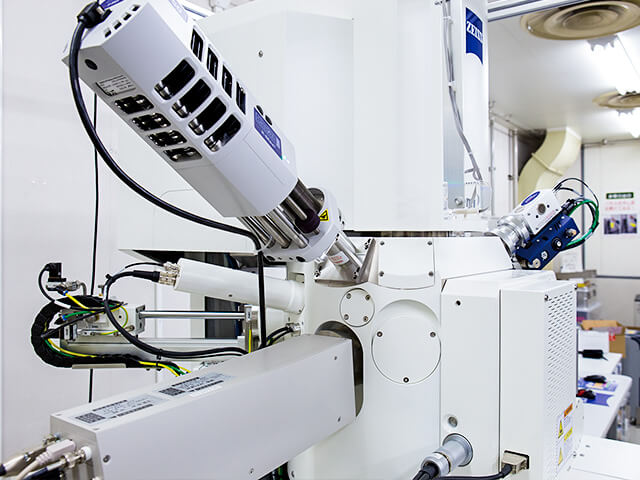

Field emission scanning electron microscopy (FE-SEM)

High-resolution observation of the fine structure and shape of material surfaces and cross sections, as well as elemental analysis and crystal structure analysis

Example:

Analysis of intermetallic compounds formed at the interface of dissimilar metals and the adhesive interface of composite materials

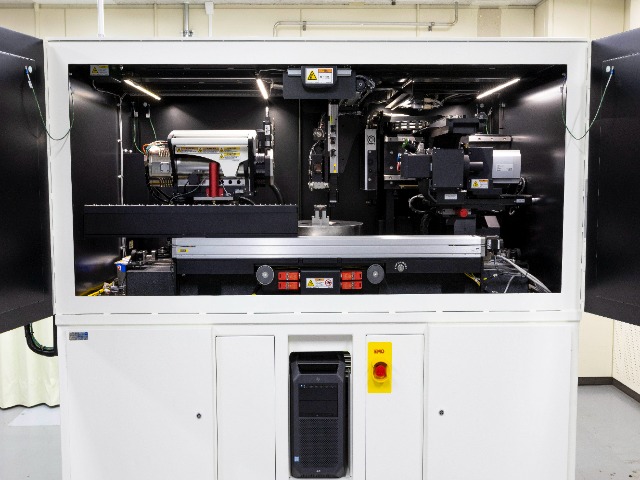

Dual Beam (FIB/SEM)

3D structure and cross-sectional analysis of the interior of materials, nanoscale processing and observation

Preparation of thin sections for transmission electron microscopy

Example:

Observation and elemental analysis of multilayer plating structure of electrical contacts

Transmission electron microscopy (TEM)

Observation of internal morphology, structural analysis, and compositional analysis of samples at atomic resolution

Example:

Observation of intermetallic compounds formed at metal-joint interfaces and identification of metallic phases.

Matrix-Assisted laser desorption/ionization mass spectrometer(MALDI-MS)

Elemental analysis and compositional analysis of organic compounds by mass measurement

Example:

Analysis of manufacturing process, thermal history, etc., using differences and changes in the mass of the molecular chains (polymers) that make up the plastic.

Fourier transform nuclear magnetic resonance (FT-NMR)

Measurement and structural analysis of hydrogen and carbon configurations in organic compounds

Example:

Analysis of the degree of degradation (hydrolysis) of polybutylene terephthalate (PBT) by analyzing the hydrogen configuration.

Liquid Chromatography-Time-of-Flight Mass Spectrometry (LC-TofMS)

Separation of compounds mixed in sample solution and measurement of content for each compound

Example:

Determination of the concentration of antioxidants and ultraviolet inhibitors contained in plastics

Laser ablation inductively coupled plasma mass spectrometry (LA-ICP/MS)

Mapping analysis of trace elements in solid samples (two-dimensional display of elemental concentration distribution)

Example:

Two-dimensional visualization of the distribution of elements that have permeated electrical wire insulation

Laser Raman Microscope

Quantitative and qualitative analysis of the components and properties of a substance using the wavelengths (spectra) specific to the molecules that compose the substance.

Example:

Relative amount of material, layer thickness (single layer to several hundred nm)

Crystallinity, state (compression/elongation), temperature

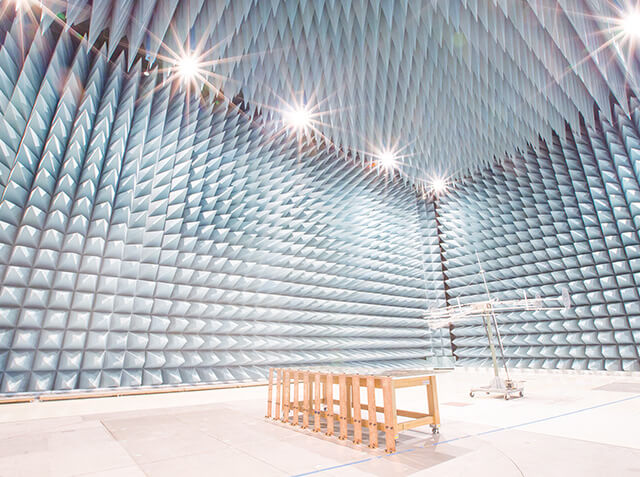

Electromagnetic compatibility (EMC) evaluation facilities

Large anechoic chamber(1room)、Anechoic chamber for vehicle components(2room)

Main use:

EMC testing for vehicle components, consumer and industrial equipment, and vehicles

Support for international standards and car manufacturer's requirements

ALSE metod, TEM cell metod, Portable transmitters, BCI metod, etc.

Equipment specifications and equipment:

Semi anechoic chamber, 10m method,

EMI Receiver, Antenna, RF Power Amplifier, Turntable

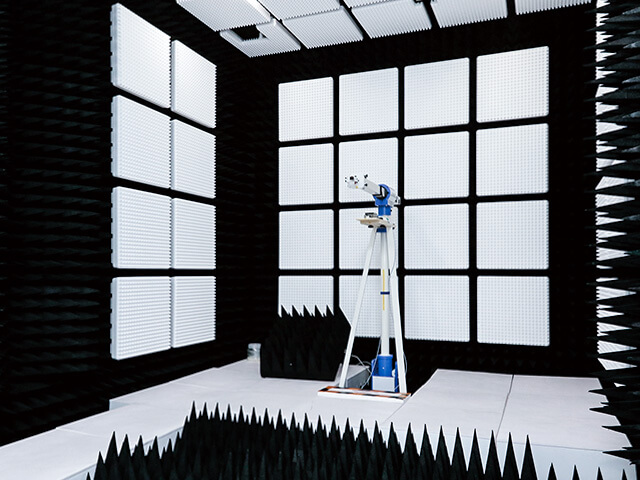

Full anechoic chamber for Antenna evaluation

Main use:

Intentional radiation pattern measurement from the antenna

Equipment specifications and equipment:

Full anechoic chamber,network analyzer

Measurement frequency is from 700 MHz to 28 GHz

Shield room

Main use:

EMC analysis by measurement and visualization of near electromagnetic field distribution of electronic products

Equipment specifications and equipment:

EMI tester, Network analyzer