Continuous copper casting and rolling machine, Fuji Factory (2014)

Episodes in Yazaki’s development and business growth

This section presents episodes describing Yazaki product development,

through which our predecessors brought wire harnesses and many other flagship products to the world.

HOME Episodes in Yazaki’s development and business growth Aroace: Overcoming obstacles buoyed on the founder’s adventurous spirit

Aroace

Aroace: Overcoming obstacles buoyed on the founder’s adventurous spirit

A desire to make completed products, not parts

In December of 1966, Yazaki Corporation began producing a product called the “Arorizer.” Propane gas has a tendency to lose pressure during the winter, which inevitably requires the installation of more gas cylinders to compensate. Arorizer is an LPG vaporizer; in other words, it is a devise for the forced vaporization of propane gas. Yazaki’s founding president, Sadami Yazaki, had extraordinary expectations for this product. This was because, although Yazaki had grown rapidly with wire harnesses, meters and other automotive parts as well as electric wires ever since its foundation, Sadami’s earnest desire was to “produce completed products, not parts.” The company constructed a new 3,000-tsubo (9,917 m2) factory in Hamana to produce Arorizers. Sadami also ordered the company’s sales arm to make greater efforts to sell it. However, the product being produced was not designed for sales to ordinary households.

Then one day, a gas company asked, “Do you have any products for consumption of gas during the summer, too?” The summer is typically not a good time for the gas industry. “How about an absorption water chiller-heater run by gas?”

A survey revealed that such a device existed in the United States. However, it turned out that, among all cooling machines, the compact and absorption type is the most difficult to produce. With this knowledge, Yazaki boldly took on the challenge of developing a small absorption-type chiller-heater in order to add a completed product to its lineup.

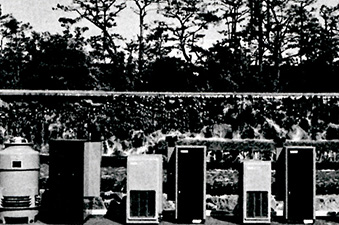

Yazaki’s “ace,” the Aroace.

An absorption-type chiller works by first evaporating water in a vacuum at just 5 degrees Celsius. It then provides air-conditioning by cooling water in a cold-water coil with vaporization heat that was generated at this time. The evaporated water vapor is absorbed by a concentrated lithium-bromide solution that has high absorbency. The attenuated absorbing solution is then heated with a burner or other heat source and restored to its water and concentrated absorbing solution elements. Because the heat exchange requires an environment that is as close to a vacuum as possible, manufacturing the vacuum vessel demanded sophisticated welding technology.

The work of devising the welding technology was conducted through trial and error by veterans with twenty years of experience. It paid off about a year later when it was decided to move away from conventional coated welding and use new TIG and MIG arc-welding technologies. Because the absorbing solution uses lithium bromide, there were concerns about the occurrence of hydrogen gas. This difficult problem was overcome with technical cooperation from Alcoa Inc. of the United States.

The first device was finally completed in the autumn of 1970. A greatly pleased Sadami declared, “This is Yazaki’s ace gas device. We’ll call it Aroace.”

Sales began in February of the following year. To meet Sadami’s order to “get ready to begin mass production immediately,” a new larger factory capable of producing between 1,500 and 2,000 units a month would be needed. Accordingly, construction of the Hamana Factory, a 12-billion-yen facility built on a 303,600-m2 site, began in 1972.

Aroace returns to the limelight.

Thus the Aroace was born, the result of a desire to fulfill the founding president’s dream as well as a large-scale investment project upon which the company’s very future had been staked. However, just one year later, at the end of 1973, Japan was visited by the era’s first oil crisis. This crisis was a direct blow to the Aroace, an expensive air-conditioning system. Moreover, the domestic economy suddenly cooled as a result of emergency belt-tightening by the government. Yazaki’s overall management situation was also seriously affected, a circumstance for which large-scale investment was partly to blame. And then came what seemed to be the final, tragic blow. On August 27, 1974, Yazaki Corporation learned of the sudden death of Yazaki’s founding president, Sadami Yazaki.

To break out of this predicament, then-President Yasuhiko Yazaki led Yazaki’s management in executing emergency measures. It sold off a total of 20 billion yen in assets owned under the Yazaki Group’s nerve center, the company’s head office in Tamura-cho, Tokyo (now Nishi-Shimbashi, Minato Ward). One of the assets sold was the Hamana Factory, which had just been completed as the Aroace production center.

Aroace subsequently continued to face a tough fight until 1980, when sales improved with the arrival of the “New Aroace,” the first compact, double-effect device of its kind in the world. The new Aroace is available in abundant variations that range from the world’s smallest 3-RT (refrigerated ton) model to a large 200-RT model. Moreover, the “Wood Pellet-fired Bio-Aroace,” which uses wood from forest thinning and other materials as its heat source, is “carbon neutral,” meaning that its CO2 emissions amount to zero. It is therefore attracting enthusiastic attention from progressive enterprises and local governments as an air-conditioning system that helps prevent global warming by reducing CO2.

EPISODE SELECTION

EPISODE 01 Aroace: Overcoming obstacles buoyed on the founder’s adventurous spirit

EPISODE 02 The egg lays the chicken: The secret story behind the birth of the wire harness

EPISODE 03 A drum business that conserves valuable wood resources and recycles waste plastic

EPISODE 04 “LP10”: The gas meter that changed how people think about propane

EPISODE 05 Moving toward a sustainable future as a pioneer in the use of solar heat

EPISODE 07 From the quagmire of labor dispute rose the grand flower of the meter

EPISODE SELECTION