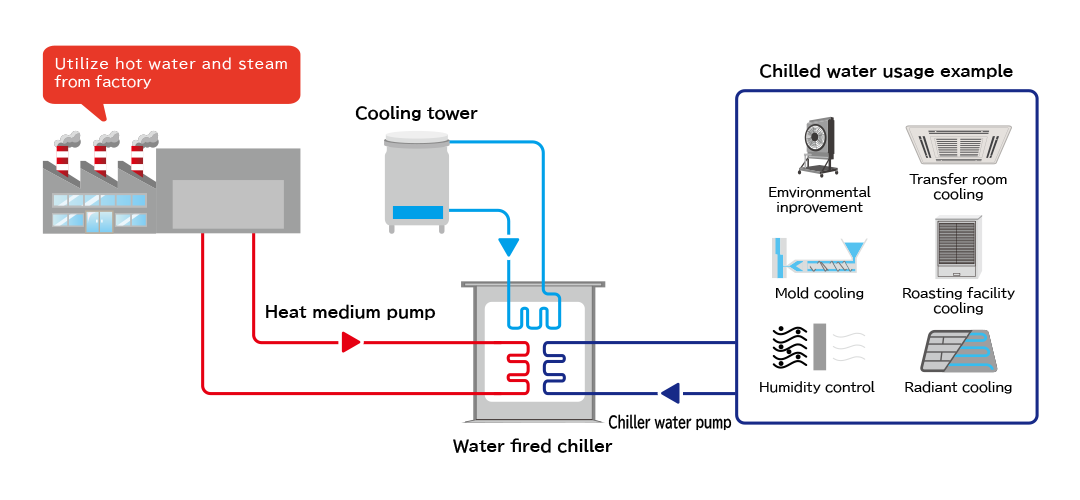

Factory waste heat utilization

Overview

In many cases, heat such as exhaust gas and exhaust steam emitted from factories is thrown away without being used. By converting this heat into chilled water with a waste heat utilization machine and using it for the base operation of existing air conditioners and chilled water generators, it is possible to significantly reduce the energy consumption and CO₂ emissions of existing machines.

Gas equipment manufacturer

Use of waste heat from aluminum diecast furnace

| Business type |

Gas equipment manufacturer |

|---|---|

| Model |

Water fired chiller 10RT |

| Available heat |

51kW(waste hot water) |

| Chilled water application |

Factory air conditioning |

| Energy saving |

79,620(kWh/year) |

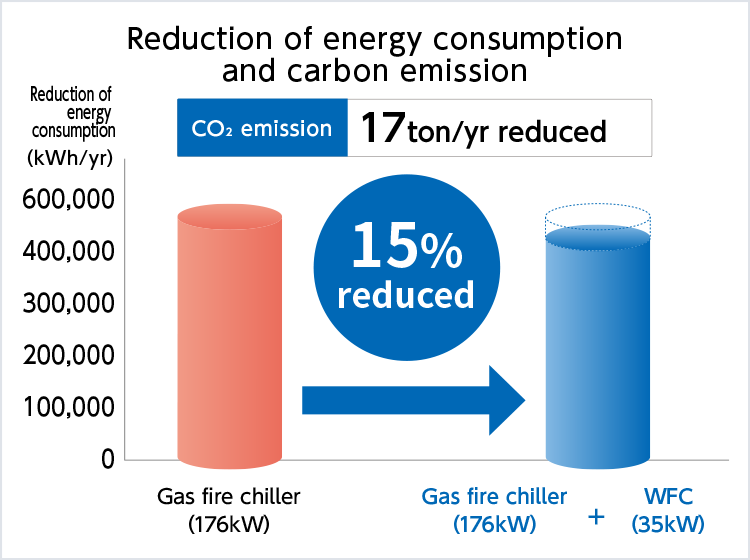

Proposal content

Added a waste heat utilization machine (cooling output 35kW) to the existing gas fired absorption chiller(cooling output 176kW).

Energy consumption and CO₂ emissions are reduced by covering the base operation of existing equipment with waste heat utilization equipment.

Confectionery factory

Use of compressor waste heat

| Business type |

Confectionery factory |

|---|---|

| Model |

Water fired chiller 30RT |

| Available heat |

151kW(waste hot water) |

| Chilled water application |

Air conditioning in transformer room |

| Energy saving |

153,400(kWh/year) |

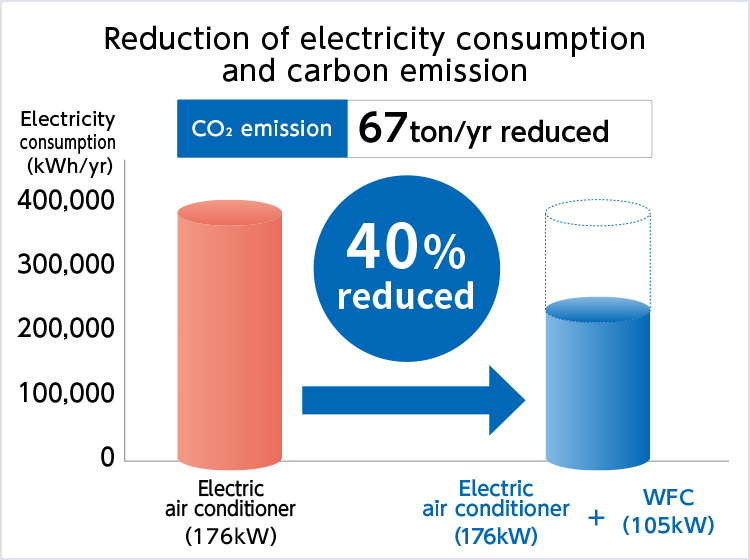

Proposal content

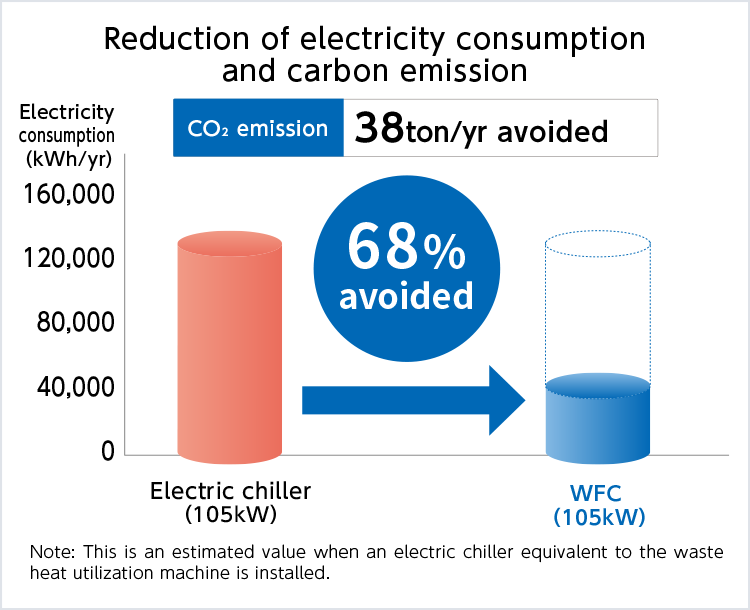

Added a waste heat utilization machine (cooling output 106kW) to the existing electric air conditioner(cooling output 176kW).

Energy consumption and CO₂ emissions are reduced by covering the base operation of existing equipment with waste heat utilization equipment.

Roasting factory

Utilization of roaster waste heat

| Business type |

Roasting factory |

|---|---|

| Model |

Water fired chiller 30RT 2 units |

| Available heat |

301kW(waste hot water) |

| Chilled water application |

Cooling coffee beans |

| Energy saving |

255,300(kWh/year) |

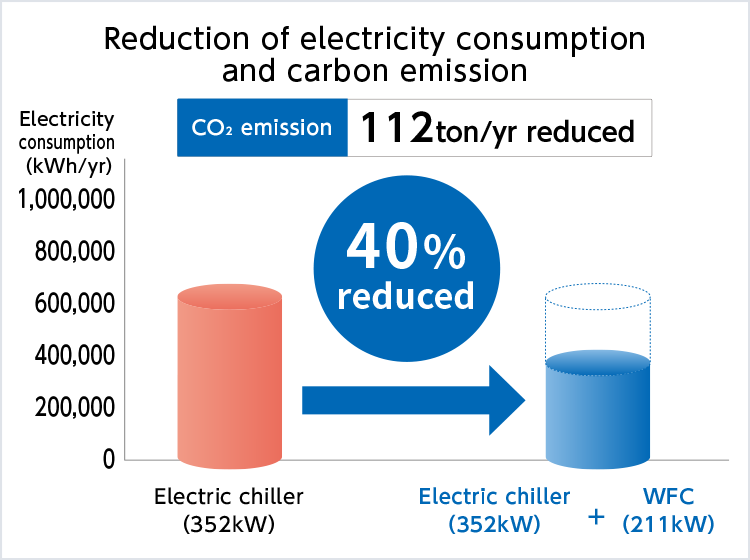

Proposal content

A waste heat utilization machine(cooling output: 211kW) was added to the existing electric cold water generator(cooling output: 352kW). Electricity consumption and CO₂ emissions are reduced by covering the base operation of existing equipment with waste heat utilization equipment.

Poultry farm

Use heat from chicken-manure-fired biomass boiler

| Business type |

Poultry farm |

|---|---|

| Model |

Water fired chiller 30RT |

| Available heat |

151kW(waste hot water) |

| Chilled water application |

Radiant cooling in a poultry farm |

| Energy saving |

87,480(kWh/year) |

Proposal content

Installed a radiation cooling system for poultry farm using biomass energy. Improved the chicken breeding environment without increasing CO₂ emissions.

Waste heat utilization web simulator

By entering waste heat related information(temperature, flow, rate), the simulator offers you the best waste heat utilization equipment.

Related product introduction

Water fired absorption chiller

New WFC series

(Refrigeration capacity 35 to 175kw)